The Precision and Versatility of Diecasting

The Precision and Versatility of Diecasting

Blog Article

Diecasting is a highly sophisticated manufacturing process that plays an crucial role in the production of complex metal components with the highest precision and reliability. This technique involves injecting the molten metal in a mold cavity with high pressure permitting the creation of precise shapes and intricate design that is difficult to create using other techniques. Diecasting is widely used across diverse industries like electronic, aerospace, automotive and even consumer products because of its effectiveness and capacity to manufacture quality parts. This article explains how diecasting works, detailing its process, benefits, and potential applications.

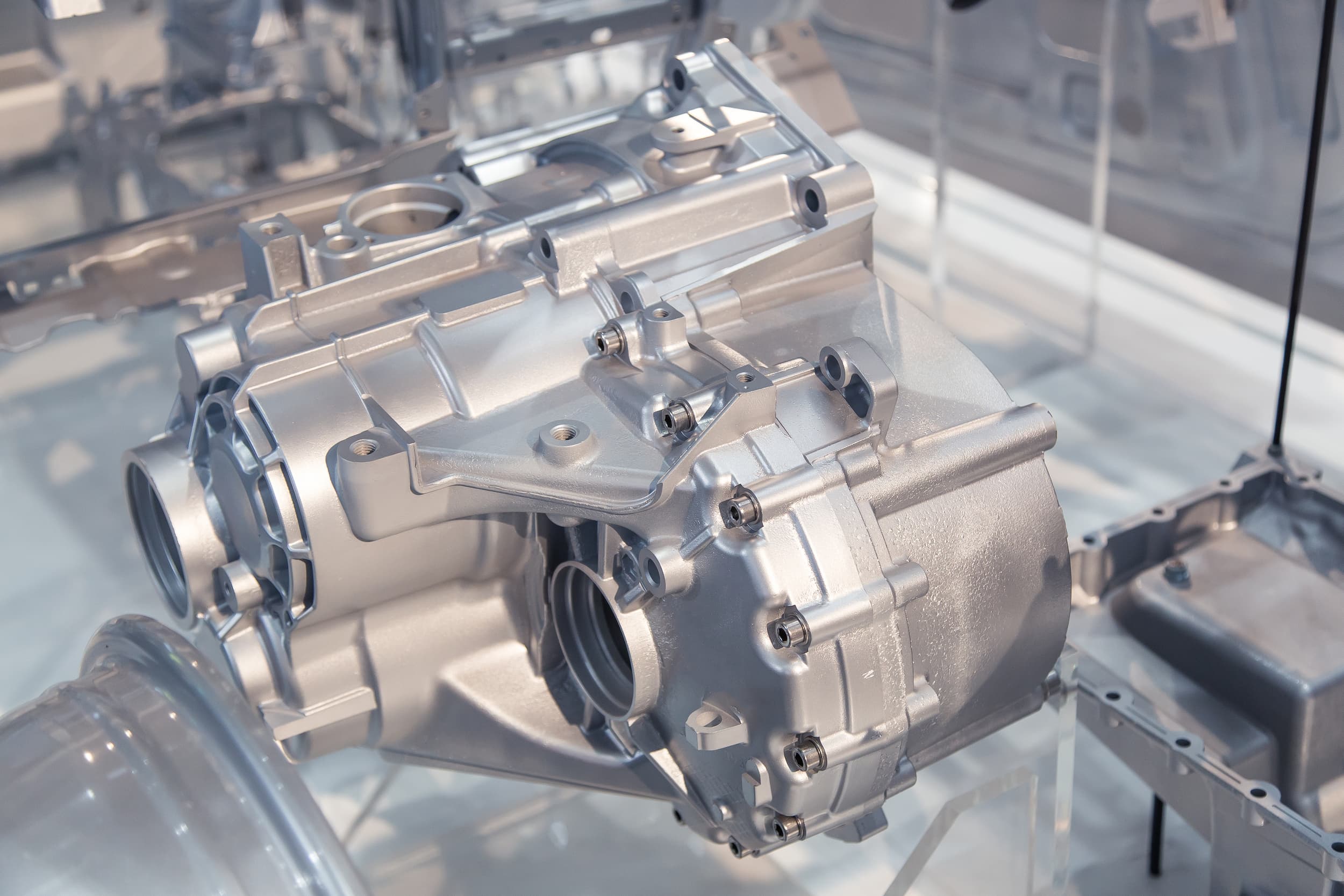

The diecasting process begins with the creation of top-quality steel molds, known as dies, which are designed to stand up to the extreme pressures and temperature of the molten metal. The dies are meticulously designed to take in intricate details and ensure tight tolerances and ensure that each part is in compliance with the specific requirements of design. During the casting process, metallic components like aluminum magnesium, zinc, and copper melt and are injected into the die cavity under high pressures. This quick injection, and its subsequent cooling produces parts that exhibit excellent dimensions and an even surface. Precision of the dies permits the making of components with complex geometries typically impossible through other manufacturing methods.

One of the major benefits of diecasting is the efficiency in the production of mass quantities. When the dies are made it can be repeated thousands or hundreds of instances with very little variation between components. The high degree of repeatability is essential for industries that require large volumes of identical components. Additionally, diecasting is known as an efficient material. It produces less waste compared to different metal-forming methods, as excess metal can be reused and recycled. It not only lowers costs for materials, but it is also a part of better sustainable production practices. This combination of efficiency, speed, as well as material efficiency make diecasting a viable solution for manufacturing large quantities.

Diecasting is also a great option with regard to the mechanical properties and performance. Diecast components are well-known for their durability and strength, which are essential features for parts used for demanding tasks. Fine-grain formation that occurs during the rapid cooling of the metal contributes to these excellent properties, which make diecast components suitable for use in environments with high stress. Furthermore, the process of diecasting permits the integration of thin walls as well as complex elements without degrading the quality of the item. This is especially beneficial in the automotive and aerospace industries, where weight reduction but maintaining strength in the structure can be crucial to boost energy efficiency and overall efficiency. To find new information please check this great site

The materials you choose for diecasting has a significant impact on the characteristics and efficiency of the final product. Aluminum is one of the top choices because of its superior strength-to-weight ratio, corrosion resistance along with its excellent electrical and thermal conductivity. These qualities make aluminum an ideal choice for aerospace and automotive applications where weight reduction is a major concern. Zinc alloys are strong as well as ductility. These make them suitable for parts requiring fine specifics and durability. Magnesium alloys are among the lightest metallic structural elements, offering the advantage when weight reduction is crucial. Copper alloys, while typically used in less applications they are highly valued due to their excellent electrical conductivity as well as their resistance to corrosion. Each one of them has its own advantages which allow companies to pick the best option for the application they are looking for.

Diecasting is the pinnacle of technology for manufacturing, providing an unbeatable blend of precision efficiency, and versatility that's unmatched by other processes. Its ability to make intricate, high-end components that have superior mechanical properties makes it a necessity in a variety of sectors, from automotive to consumer electronics. The efficiency and material savings associated with diecasting demonstrate its worth in high-volume production, while its adaptability makes it able to satisfy the ever-changing demands of modern manufacturing. While industries push into the realm of creativity as well as performance, diecasting will continue to be an essential tool helping to advance technology and facilitate manufacturing of the most cutting-edge items that shape our world.